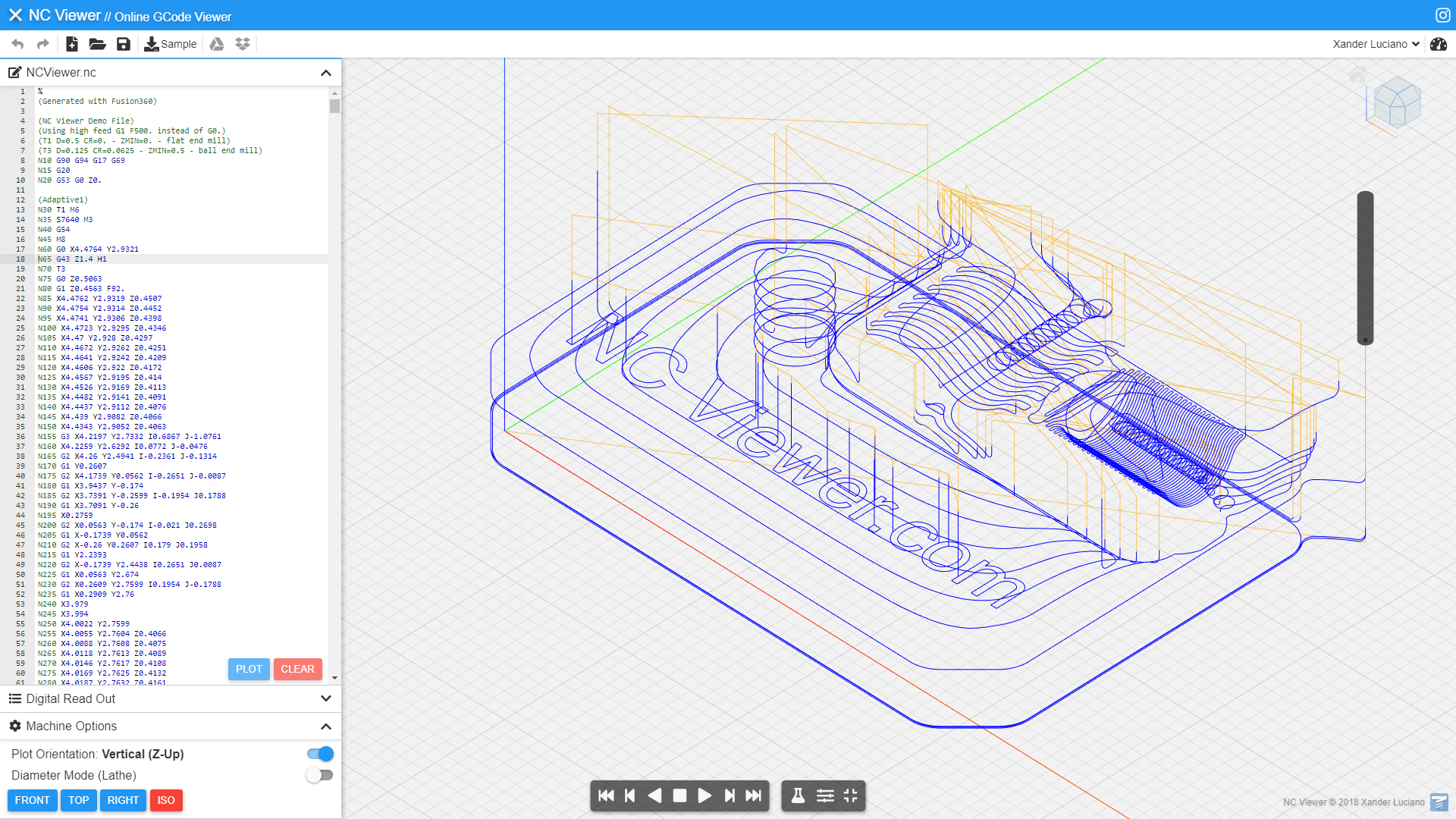

What it needs is the start position, end position, and how wide and tall your extruded track should be. So, let’s start with the simplest example, let’s make a line. Now, the closest thing this reminds me of is programming a CNC using the built-in features of something like a Heidenhain controller, but in the case of Full Control GCode, you don’t need to know any actual gcode to use it, because the generation of the gcode itself all happens based on the features you set up. So basically, you just download the Full Control GCode Excel sheet, open that up, enable macros, and you’re off to the races. I signed up for the Microsoft office 30-day-trail because this absolutely does not run in the free LibreOffice, or in Google Docs. Full Control GCode is written entirely in Microsoft Excel and its Visual Basic Macros functions.

Knowing even some basic spreadsheet stuff has come in handy for me so many times already and in the case of Full Control GCode, it’s actually the only thing running the show. If anyone ever tells you “you need to learn how to work with spreadsheets”, and you just go “boooooring” – don’t. So let’s check out Full Control GCode, what it does, how it works, and what you can’t quite do with it yet.

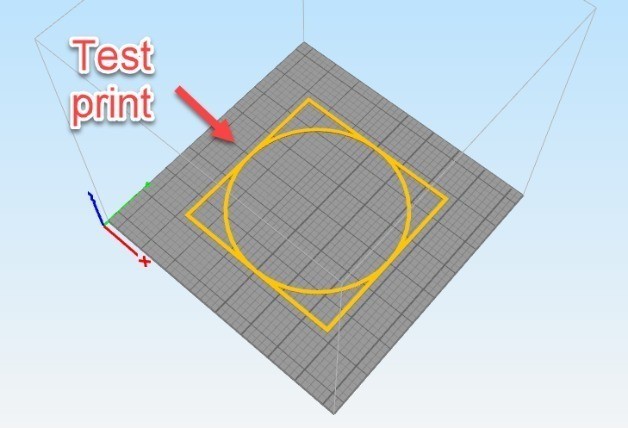

This part is a battery mounting plate for standard lithium-ion cells that I need to print 24 of, and I managed to get it from two hours of printing down all the way to just under 30 minutes with a functionally identical version crafted in Full Control GCode – and that is without cranking up the print speed. 30 min print time in Full Control GCode.And that lets you do some incredible stuff that would be nearly impossible to model first, but it also allows you to specifically craft and optimize functional parts to make maximum use of the specialties of filament-based printing. Andrew Gleadall, and it lets you skip modeling and slicing and instead provides you with a scripting interface that controls every single printing move. This is actually the result of a research paper by Dr. Except that it doesn’t have to be that way. You start out by creating a 3D model, export that as stl or 3mf, then import that into a slicer, which then creates the gcode that the printer understands.

Okay, you all know how 3D printing works. Full Control GCode is a new approach to getting your 3D printer to print *exactly* what you want! And it’s not just useful for creating weird vases, it’s actually a great tool to make functional parts as well.

0 kommentar(er)

0 kommentar(er)